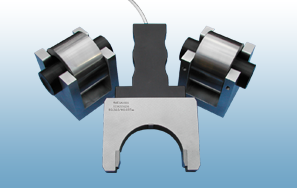

Bearing Diameter Air Caliper Gauges

These gauges are used extensively for bearing journal diameter measurement in automotive engine applications. Gauging in up to three places (3 pairs of jets across the diameter) this can show taper, diameter & ovality of the journal quickly and easily.

Ranging of the caliper via master setting discs is easy & straightforward. Readout can be by Air/electronic converters to VC2000 columns or by Clearline. The gauges can be manufactured to operate with other gauging systems.

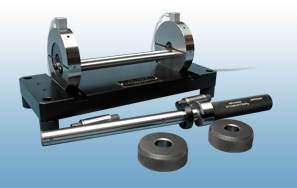

Matching Gauge Fixture

This Gauge compares component bores with close fitting component outside diameters. The readout, in this case three VC2000 columns via air/electronic converters gives the outside diameter of one component on the first column, the inside diameter of its matching component on the second column and the clearance or interference fit on the third column. The operator can see the sizes clearly as they approach the required fit .

Concentricity Squareness Gauge

The three gauges mounted on an integral base as shown are to check the relationships of various component features to each other.

On the left two air plugs (for two different components) check squareness of end faces to bores whilst the right-hand plug shows the relationship between the outside and the inside diameters of the component.

Setting masters are shown alongside three air/electronic converters c/w electronic probes, an air filter regulator unit fitted with a four way manifold and an electronic readout. These gauges are equally at home with Clearline, Air/electronic and other gauging systems.

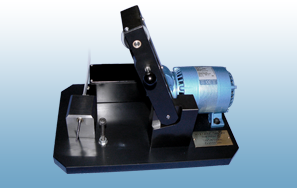

Motorised Concentricity Gauge

The concentricity measurement of small bores on fuel injector nozzles and other small components can be measured by our concentricity mandrels custom designed and built to suit your application. The fixture shown to the left is motorized to enable the component to be rotated. Any concentricity can be seen on an electronic readout.

This close up picture shows above the air plug gauge, the drive wheel that is connected via a drive belt (under guard) to a reduced speed motor giving a speed slow enough to measure the component successfully. The fixture is shown here with the drive in its ‘parking’ position. The air is fed out via 2 metre long air hose to in this case a Clearline unit. It is equally at home with an air/electronic system with its extra versatility ie. RS232 output allowing computer interrogation of the readouts for SPC purposes etc.

Have a Gauging Enquiry?

Customers are actively encouraged to work alongside us to arrive at suitable gauges and fixtures to satisfy their special gauging requirements

Call us, either Sales or Design.... see Contact Page for details